Table of Contents

What is a ceramic kiln?

According to the Royal Spanish Academy (RAE), a pottery kiln is an “appliance for the treatment and transformation of mineral matter by means of heat”.

In other words, a pottery kiln is a tool that every potter needs to give a solid shape to the figurines he wants to make out of clay.

Brief history of the pottery kiln

Before the kiln was invented, our ancestors baked their pieces of clay around an open fire.

Then they placed the objects in a pit with walls made of straw and clay. Realizing that this led to better results, around 4,000 B.C. Stonewalls surrounded by sand to insulate the construction even more.

In China and Japan, too, holes were dug in the ground and then surrounded with walls of stone and sand. Its interior was large enough for a human to crawl in and place the clay objects.

Over time, the ovens were no longer buried but set up above ground. Then, around 400 AD, the Korean raw furnace was born. It was so named because the heat was conducted into the furnace through a pipe.

In the 10th century, these kilns were improved in the Middle East to compete with products made in China. This is when the so-called chimneys were built.

In 1708 and 1720 the furnace was renewed in Europe and coal began to be used as fuel. The grates are made of cast iron to improve their resistance. The kiln that was created there was called a bottle kiln, where the flames went from the walls to the middle and the pieces could be fired more optimally.

In 1858 curved or straight continuous furnaces were developed, which were designed in such a way that the heat and temperature inside them remained constant.

Later in the 20th century, liquid and gaseous fuels began to be used.

Finally, in 1900, the first test kiln was developed, which is still used today by potters to produce ceramics.

Types of pottery kiln

Now that you know the history and development of this tool, it’s time to talk about the types of ovens that exist today.

Test or laboratory kilns

Test or laboratory kilns are so called because they are used for the test firing of clay of all kinds. It is also used to check the temperature to which a particular piece is to be exposed.

This type of furnace uses gas as fuel and can reach temperatures of 1,200 to 1,300ºC.

There are different types of laboratory kilns:

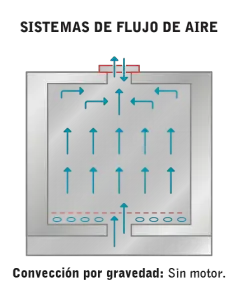

Gravity convection kiln

This oven transports the heat through different zones and at different temperatures. It usually takes 45 minutes to an hour for the temperature to stabilize.

The drying cabinet is mainly used for drying materials that are resistant to high temperatures, such as B. Porcelain.

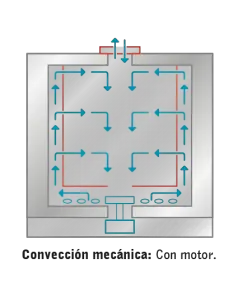

Forced air convection oven

Like the drying cabinet, the warming cabinet can transport heat between different zones with different temperatures.

This oven is used to dry and dehydrate substances that must be exposed to clear temperatures that must not be exceeded since they are very delicate parts.

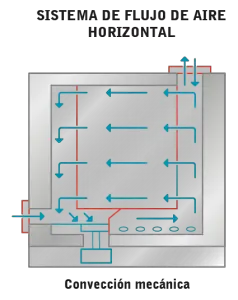

Horizontal continuous kiln

Its name comes from the fact that the heat flow it transfers is horizontal. The stabilization time at a fixed temperature is between 25 and 40 minutes.

This kiln is used for drying all kinds of materials and clays.

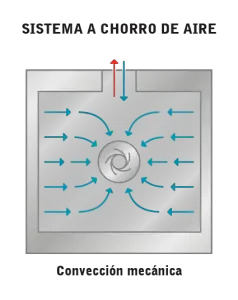

Air jet or sterilization kiln

This furnace is called that because the heat flow it generates is transported to the center of the furnace in the form of a jet of air. It takes an estimated 15 to 20 minutes for the temperature to stabilize.

This oven reaches a temperature of 220ºC. and is used for the sterilization of stainless materials and glass.

Vacuum kiln

The vacuum oven takes 20 to 35 minutes to stabilize the temperature, which can reach 200ºC.

This kiln is used for drying, firing and curing different types of clay.

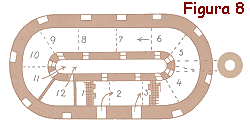

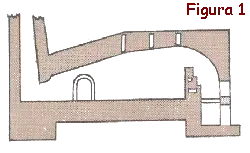

Annular kiln

This kiln was invented in 1838 for making bricks or clay objects such as crockery. Its original circular shape characterizes it, as the firing object moves in circles around the still fire.

This type of kiln has 12 chambers that the object passes through during the firing process. There are different temperatures in each chamber, which makes it possible to control the perfect firing of the object.

Nowadays there are also elongated and straight ring furnaces where the heat flow process is the same. This type of stove has the advantage of using less energy and saving energy by using natural gas as fuel.

However, these ovens are no longer widely used as there are many other options that are easier to handle and smaller, such as: B. Electric ovens, which we will discuss later.

Tunnel kiln

The tunnel kiln is characterized by the fact that the fire moves around the object to be heated.

This type of oven works in a special way. Inside is a mechanism resembling the rails of a train through which fire moves. It should be emphasized that the fire in each chamber becomes stronger or weaker depending on how much power or temperature the object to be burned requires.

Tunnel kilns are mainly used for firing porcelain. They use gas, oil or electricity as fuel.

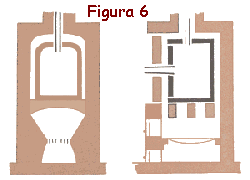

Muffle kiln

Characterized by its simple and elongated shape, this oven has a door that allows access to the inside of the oven to place the piece to be burned. It also has a peephole through which the potter can watch the entire firing process.

The gas is transported from the bottom of the kiln to the center where the object to be burned is placed. There is an opening at the top of the oven through which the gases emitted by the oven during operation escape.

This kiln is used to fire porcelain and earthenware, but also to fire the paints and glazes used to paint them. This furnace is fired with natural gas or propane.

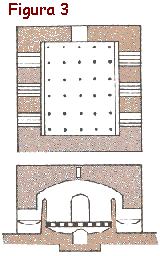

Chamber kiln

This type of oven comes in two shapes, round and square. But regardless of their form, the functions remain the same.

This oven can have up to three tiers, each tier dedicated to baking different types of ceramics at different temperatures. The three-tier kiln is used to fire porcelain. The two-tier kiln is typically used for firing glazed pottery.

The heat flow is vertical, from bottom to top. This type of furnace uses coal, oil or gas as fuel. As the heat rises, it concentrates here, burning the object into clay. The chamber furnace also has an opening at the top through which the gases can escape.

Another important point for you is the fact that it can reach temperatures of up to 1100ºC.

Kasseler kiln

This is an ancient kiln used for firing tiles and pottery such as crockery.

Its structure consists of an elongated interior, which is why heat is transported horizontally. The heat travels from the bottom right to the center where the piece to be burned is located and finally releases the gases through the hole in the top left, allowing more oxygen to be delivered to the object inside.

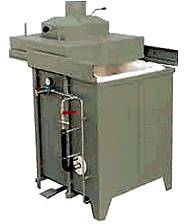

Electric kiln

Electric kilns are the most common in the ceramics industry these days because they are very convenient to use.

Inside these kilns, there are some channels in the walls through which the heat is transported and which allow the desired temperatures to be easily maintained.

Another benefit of these kilns is that they can reach temperatures in excess of 1450ºC, meaning the potter can fire all types of clay at any desired temperature. Usually, these ovens are between 1 and 2 m high.

Gas kiln

Gas kilns are also widely used by potters because they are easy to use.

This type of oven is similar to the electric oven, with the big difference that it has to be powered by gas cylinders.

Important: For safety reasons, the gas bottles or cylinders should always be placed far away from the stove, as we want to avoid accidents.

An advantage of this oven over all of the others above is that it can reach and maintain any temperature in minutes.

Its main disadvantage is that it is very heavy and large, usually over a meter high, so transporting it is quite complicated and can become a problem for the potter using it.

What to consider to purchasing a kiln

Now that you know what types of pottery kilns there are, we can move on to the aspects that you should not forget before purchasing this essential tool for making pottery.

Size of the pieces

Before you buy an oven, you should think about the size of the pieces to be made.

If you are only focused on small jobs, a small oven is sufficient. However, if you were aiming for more challenging pieces, you should get an appropriately sized oven.

Even if you only want to make small pieces at first, we recommend that you choose an oven with which you can also make larger pieces in the future.

Pricing

Oven prices vary according to size and whether they are gas or electric, which are the most common these days. Please note that prices for electric and gas stoves can range from USD 150 to USD 4,000.

We advise you to look for recommendations and comments from people who have already bought and experienced this product, or any brand in general.

Power consumption

Most of the ovens on offer are electric. Before making a purchase, however, you should find out about the consumption. The connection is also a crucial factor. Can the stove be powered from a regular outlet or does it require a special installation with a higher output?

Lifespan

Even if you are just starting out with ceramic work, you should think about the future before making a purchase. The size and performance characteristics should be chosen in such a way that a furnace can also keep up with its own progress.

Space usage

Ovens can sometimes take up a lot of space. It should be noted that not only does the device itself require space, but that you may also have to take appropriate distances into account.

If you can place the oven, but the door cannot be opened due to the space available, the choice was probably bad. It is important to allow enough space to move around the stove.

Where can you buy a ceramic kiln?

Gas and electric kilns for ceramics are the most commonly used by potters these days, so one can find many options for these two types of kilns on the market. These ovens can be purchased online or in dedicated stores.

If you decide to buy a stove in a store, you have the advantage of being able to consider the stove in detail and clarify all your questions with the sales consultant.

On the other hand, if you want to buy your oven online, you should always make sure that the websites where you make your purchase are safe and that they give you a guarantee for your product.