One of the basic tools of a potter is the potter’s wheel. There are many different potter’s wheels available today and it can be difficult to choose.

Table of Contents

Brief history of the potter’s wheel

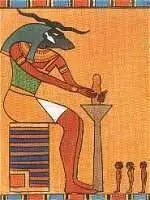

Although the date and location are not confirmed, the potter’s wheel is believed to have been invented in Egypt around 3,000 BC. There is an image of a potter’s wheel and the god Jnum appearing and forming a clay body representing his soul.

However, there are reports that the wheel appeared in Mesopotamia around 3,500 BC. However, it was not used for vehicles, but for the manufacture of pottery and irrigation.

Potters of that time used the wheel manually and turned it with their hands. After the first swing, the potter had a few seconds to shape the clay and create his piece.

In the Mediterranean area, the potters also made the potter’s wheel their own as this tool made the work much easier. At that time there were already variations in the size and height of the wheel, which made it possible to create objects of different sizes.

Later, in the Iberian culture, the potter’s wheel was further developed. A low lathe made of wood was created. To make this work, an axle was mounted. Thanks to this axle, the wheel could rotate much longer, which made the potters’ work easier.

By the 1820s a steam engine was adapted and modified to work with molds, allowing similar pieces to be produced in less time. This era has been seen as the reinvention of the potter’s wheel because of these advances and changes.

What is the potter’s wheel?

The potter’s wheel is the most well-known tool in the field of ceramics. Potters use it to shape their clay pieces.

Parts of the potter’s wheel

The potter’s wheel consists of the following parts:

Seat

This is the most basic part and as the name suggests, it is where the potter sits. This seat should be above the steering wheel.

Hand wheel

The hand wheel is the large wheel, usually made of wood, at the bottom of the potter’s wheel. The hand wheel is turned with the potter’s foot, which also allows the chuck to turn.

Plate, crucible or wheel

All three terms are possible because the clay is placed on this object in order to be shaped as it rotates.

Easel

This part of the potter’s wheel has the function of a table on which the potter can place objects that he needs and needs to have nearby. This part is usually made of wood or iron.

Pedal

As you will see below, there are two types of manual potter’s wheels, one of which is equipped with a pedal that the potter uses to rotate his plate. This pedal is located underneath the chuck.

Vertical axis

This part of the lathe consists of a straight or curved rod that connects the pedal or hand wheel to the chuck. This allows the connection between these parts and ensures that both can rotate at the same time.

Manual lathes

Manual lathes are among the oldest and simplest lathes. As the name suggests, these lathes are operated manually, i.e. with the potter’s hands and/or legs.

There are two types of manual lathes:

Wheel lathe

Experienced potters typically use these lathes. The potter turns the wooden base with his foot to make the wheel spin and mold the clay.

Treadle lathe

The treadmill is similar to the traditional potter’s wheel, the only difference being the way the potters use it.

The correct use of this lathe is that unlike the rotary disc, there is a pedal that must be operated by the potter and this is how the potter turns the lathe. However, it has the disadvantage that you cannot control the speed at which it rotates.

Advantages of manual lathes

- These are not easily damaged and will last for a long time.

- They are easy to use for both right-handed and left-handed users as they can be rotated clockwise or counter-clockwise.

- For some potters, this lathe makes shaping the clay easier and helps shape even very thin pieces.

Disadvantages of manual lathes

- They are very heavy and therefore not easy to transport.

- Continued use over long periods of time can cause problems for Potter’s Knee.

Electric lathes

Thanks to progress, lathes have also evolved. Today there is a large selection of electric lathes.

Electric lathes may have foot-operated pedals. But there are also those without a pedal, which turn immediately with electricity.

Nowadays there are small electric lathes with a wheel under which is a base on which the wheel stands and houses the motor. This type of lathe is found in aluminum and metal.

Advantages of electric lathes

- They are small, light, and easier to transport from one place to another.

- Clay can be formed much faster.

Disadvantages of electric lathes

- They depend on electricity for their use.

- They are sometimes very loud.

What to look out for

Now that you know what types of lathes there are and what their advantages and disadvantages are, it is important that you also consider some aspects such as price, warranty, space requirements, ease of transport, type of chuck, noise level, and lifespan of the product.

Lathe pricing

Lathe prices vary depending on the size of the lathe. The price range moves between USD 80 and USD 500.

Remember that the most expensive product is not always the best, but buying twice is more expensive than buying once.

Product Warranty

Just like the price of the lathe should be considered, it is important that you consider the warranty. We recommend lathes with at least a 5-year guarantee. In the event of damage, you are therefore protected. This makes sense especially for beginners.

Lifespan

Two factors should be taken into account when determining the useful life. First, you should buy a product that has a certain lifespan.

Second, you should also buy a product that can keep up with at least a certain development of your own skills.

Space and portability

Here you should first analyze whether you will use a machine statically or whether it will change its location frequently.

Furthermore, you should measure the space available so that the machine and the user have enough space. It can also be extremely helpful here to first draw the dimensions of any machine at the desired location on the floor.

Type of wheel

There are different types of chucks with different sizes and materials. Some prefer plaster linings, others metal linings.

Metal liners are more common these days because they can handle any material with ease and are easier to clean compared to plaster liners.

We recommend metal plates as they offer advantages over plaster. The plate should also not be too small; otherwise larger pieces cannot be processed.

Noise

There are very loud lathes, which can sometimes disturb concentration. Not everyone is equally sensitive to noise. If you have the opportunity, you should inspect a machine on-site before buying it and then also check the noise.

Where can you buy a potter’s wheel?

Both manual and electric potter’s wheels can be purchased online or in related stores.

The advantage of buying a potter’s wheel in a shop is that you can examine and examine every part of the tool in detail.

When buying online, you should always exercise the necessary caution, as with any online purchase.

Our tips

If you are a beginner in the world of ceramics, we advise you to choose a small electric potter’s wheel. However, you shouldn’t decide on the cheapest junk that flies in your face the first time you use it. On the other hand, it is also not necessary to choose a professional and therefore rather expensive model.

Ideally, it should be a lathe without a foot pedal, which makes it easier to use.