Translated by Nick R

What comes to your mind when you hear the words ¨ceramic furniture or holders¨? Hold what? Do I have to buy a shelve for my kiln?

Many of these same questions came to our minds the first time we heard about these objects. That is why today, in this blog, we will answer them all and explain everything you need to know about kiln firing furniture.

Table of Contents

What is kiln furniture?

Let’s start with the basics, kiln furniture conveys holders and accessories where you hold or support your ceramic pieces into the kiln to be fired.

In this way, each kiln furniture device provides safety to all the pieces and allows them to have a uniform firing.

Types of kiln furniture

Now that you know what they are used for, it is time for you to know the different types of kiln furniture that exist.

You need to know that there are 5 kinds of furniture and that they come in different shapes, colors, sizes, and qualities. Next, we will talk about and show you each of them so you can learn about all these options of holders for your kiln.

Refractory kiln plates

Kiln plates are rectangular and can be placed inside the oven to divide into different levels, like floors, leaning on refractory tubes which support them at the height you want.

We recommend placing 3 plates so that the air and pressure can circulate better, thus your pieces are well fired and breakage-free.

There is no rule indicating the height and distance between each one, as it is determined based on the pieces you are putting in between. Just make sure that there is a 15 cm distance between the top plate and the art pieces.

Before using the plates, keep in mind that you must cover the plates with refractory plate protectors every time you fire pieces for the first time. This serves to protect it from any glaze residue or accident; for example, some works may explode if they are exposed to high temperatures that they cannot withstand.

In markets, you can find different types of plates that mainly vary in size and shape since there are round, rectangular and square, and smooth or perforated ones.

Workpiece holders

Piece holders are used when the pieces have been glazed or painted entirely and cannot be fixed together during firing, or else they could get badly damaged.

They are also called tripods because they have 3 legs or feet, as a tripod does. Supports are not designed to withstand high temperatures, they can deform during the firing process and worse if they are not well leaned on the refractory plate.

However, the good news for you is that you can get them in 3 different materials: steel, ceramic and refractory.

Steel supports can be round with one, two, three, or even four supporting points. There are several options for you to choose the one you like best.

Ceramic supports are made of refractory ceramic and have 3 supports from which emerge spikes or metal points that hold up the glazed pieces and prevent damage.

Finally, the refractory supports are those with 3 legs, each with support points upwards and downwards that hold the pieces firmly and keep them from coming into direct contact with the refractory plate.

Rod structures

Structures with rods are another type of kiln furniture for ceramic pieces, and you may ask yourself: how do they work? It is really easy, probably you have visited or seen how to roast chicken is made. Do you remember the rods crossing them as they go around and around? Well, that’s how these structures work, only they don’t spin.

These rods are made of steel, and you can get them in various thicknesses such as 2, 3, and 4 mm diameter, which is ideal for little pieces with a hole in the middle like jewelry accessories.

There’s something else! – You can make this type of holder yourself. You only need refractory tubes that you will support on refractory bricks with 8 mm diameter holes; pass the steel tubes through these holes. Then, for those pieces that do not have a hole in the middle to pass them through the steel tube, you can tie them with a wire or kanthal thread in a section you think can be painted later or where you don’t mind having the wire trace.

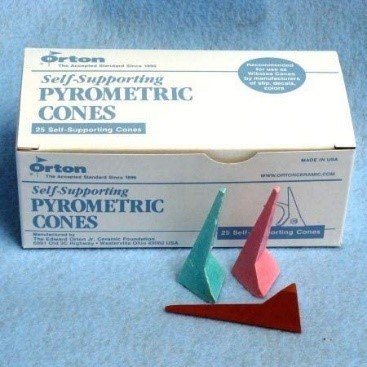

Pyrometric cones

If you think that pyrometric cones hold the pieces in the kiln, let us tell you that you are a bit far from the actual meaning and function of these pieces.

Pyrometric cones are used to measure the kiln temperature and the maturation degree of the clay inside the kiln. They are usually employed in non-electric kilns or kilns with no temperature control.

You need to know that there are 2 types of pyrometric cones: self-supporting and small cones. Then, for you to understand what each one is about, we will explain here.

The self-supporting cones measure the lathe temperature and the firing rate of the workpieces. In addition, they help you avoid mistakes and time-wasting in the firing.

The self-supporting cones measure the lathe temperature and the firing rate of the workpieces. In addition, they help you avoid mistakes and time-wasting in the firing.

Generally, these cones come in boxes of 25 units, and they include a support foot to stand the cone in the kiln.

On the other hand, the small pyrometric cones are temperature sensors for manual kilns. The cone detects when the right temperature has been reached, and then you have to manually stop the firing.

You can get these cones in boxes of 50 units or individually if you want.

Both types of cones allow you to know once the kiln has reached the desired temperature as they begin to warp or melt, at which time you can take them out and dispose of them.

You should also keep in mind never to put the cones directly on your plates, for when they start melting, they can get stuck and damage your plate. For this reason, we advise you to place them on a small refractory base which you will have to take out with the cones when reaching the desired temperature.

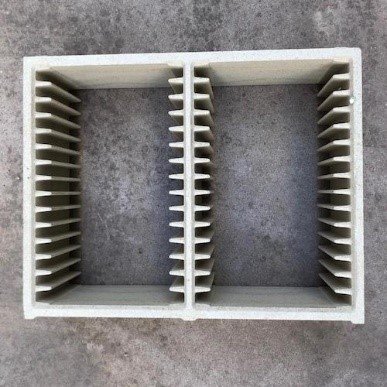

Support tubes and plate lockers

Remember we told you that you need support tubes or lockers to hold and divide your plates? Well, it’s time to show you some of these kiln support materials for your kiln.

Support tubes are made of refractory materials that resist high temperatures. We recommend installing them at different heights so that you can place your plates and your clay pieces above them.

Also, the lockers are, as its name says, boxes that can have one or several divisions which serve (to put the plates at the height and with whatever distance you want to have one from the other. Additionally, you can get them in different sizes to adapt, not only to your kiln and art pieces but also to the plates.

This is the end of this blog; we hope you have learned all about kiln furniture and what they are for. And now that you know it, it’s time for you to choose the one you like the most and the one you need for turning your pieces into beautiful artifacts.