Are you looking for a material to paint, decorate and cover your ceramic pieces? Then you need ceramic glazes that protect your pieces while leaving a beautiful finish.

Table of Contents

What are ceramic glazes and what are they used for?

Ceramic glazes are a mixture of fluxes such as alkali metal, boron, strontium, and others with quartz, which are applied to the ceramic before it enters the kiln.

It can be said that it is a decorative technique because, as already mentioned, it is a very well-known method among artisans to add color to the pieces.

The glazes are applied in such a way that the pieces are provided with a smooth, glazed layer. This turns the porous surface of the clay into a resilient and impermeable surface without any kind of porosity.

Therefore, all ceramic products into which water or other liquids are poured, such as cups, bowls, bowls, or plates, must be glazed. This not only makes the items waterproof but also more durable.

Enameling, as this method is called, is very old. It comes from the Greeks and Egyptians.

What should you consider when buying glazes?

Before purchasing ceramic glazes to decorate and protect your pieces, there are a few things to consider.

You should consider the following aspects:

- Different types of glazes

- The tone you chose

- Presentation and quantity

- Price

Types of glazes

Glazes are divided into 4 types that have specific properties:

- According to the firing temperature

- Shine and transparency

- Type of firing and surface effect

- Composition

The most important aspect is the firing temperature. From this, you can derive the other aspects and choose the right product to buy.

1. Depending on the firing temperature

Ceramic high-temperature glazes (stoneware or porcelain glaze)

High-temperature glazes are those that are fired at 1,200 to 1,300 °C. They are mostly used for stoneware or china clay as these are fired at about the same temperature.

Ceramic low-temperature glaze

Low-temperature glazes are usually fired at 950 to 1,050 °C. These glazes are available in transparent, matt, glossy, opaque and polished. They can be used on clays such as terracotta, which is fired between 900 and 1100°C, or raku, which is fired between 750 and 1100°C.

Gloss and transparency of ceramic glazes

Transparent glazes

Transparent glazes are those where, after application, you can still see the clay that the glaze was applied to, i.e. there is a transparent layer and you can see what’s underneath.

This glaze is a science in itself because in order to achieve different degrees of transparency, the temperature and the development of the firing process in the kiln are very important. In addition, how the piece is cooled.

The glaze is another aspect that can make the difference between a more or less shiny piece. For example, a glaze that favors gloss is lead.

The color of the clay used can also affect the degree of transparency. When working with red or black clay, it’s a bit more difficult to get good transparency because of the strong color.

Glossy or matte opaque glazes

As the name suggests, these glazes are opaque. This means that the light cannot penetrate through the glaze to see the surface of the work, in this case, the clay.

The reason for this is that these glazes contain opacifying elements such as tin oxide, zirconium oxide, arsenic oxide etc. which cause the light reflection to come from the surface i.e. from the glaze layer and not from the clay.

When these glazed pieces are in the kiln and the firing temperature rises, the oxides contained in the glaze release particles that are difficult to separate and form a suspended film that blocks light.

Like the transparent glazes, the opaque glazes can be glossy or matte depending on the firing temperature and the materials they contain.

Red and black clay are very welcome when using opaque glazes, as the opacity of these glazes means that the original color of the clay does not show through and so does not affect the visual result of the pottery.

Half or intermediate glazes

These glazes are right between transparent and opaque glazes, meaning they are the perfect intermediate level in terms of gloss, matte, transparency, or opacity. They do not achieve a very high degree of transparency, opacity, or gloss.

Something great that you can achieve with these glazes on the objects is that by combining glazes with different brightnesses and transparencies in different areas you can create highlights, contrasts, and aesthetic effects that look great and make the piece unique.

Depending on the firing system and surface effects

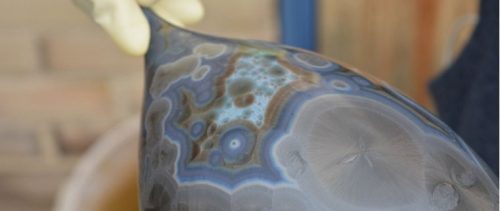

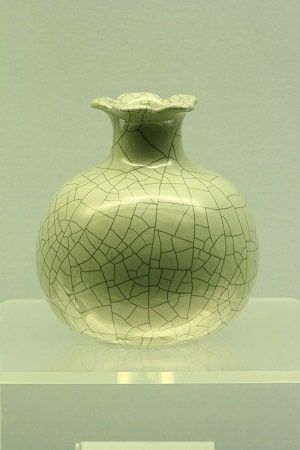

Ceramic crackled glazes

These glazes give a great look to ceramic items as they create a cracked effect on the surface due to some factors when mixing the glazes.

It is as if cracks appear in the ceramic without damaging the piece. So it’s not that the clay is cracked, it’s just a great decorative and visual effect that these glazes can create.

Glazes with crystallizations

As the name suggests, these glazes simulate crystals on the surface of the workpiece. This is achieved by overlaying two glazes applied in two layers. It is one of the glazes that can add a very beautiful and eye-catching touch to your pieces.

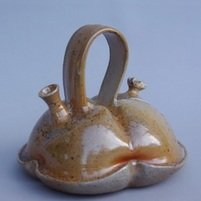

Raku glaze

Raku glazes are intended exclusively for the raku decoration technique. This is because the pieces are washed very well with water and powdered soap in the biscuit, i.e. after the first firing, and then dried in the sun.

When the piece is dry you have to touch it very carefully because when it comes into contact with the natural grease of the hands and then the enamel is applied and dries again the structure can change. It is best to wear gloves.

To apply the enamel, 3 known glazing techniques can be used: pouring, dipping, and brushing. Then the piece has to be placed in a kiln at a temperature of 900ºC, depending on which glaze you use, because as you have already seen, there are glazes with lower or higher firing temperatures.

With this technique, the pieces are removed from the kiln before they cool and placed in a container with sawdust or wood shavings. This ignites the shavings and creates a tremendous amount of smoke that penetrates the piece, staining it and turning it into another layer of the piece.

Glazes according to their composition

Lead glazes

Due to their main ingredient, lead, these glazes are not recommended for commodities, particularly items that come in contact with food, such as B. Dishes.

However, they can be used for earthenware, i.e. for decorative objects, as they are very shiny, can be easily colored with dyes and remain transparent after firing. To fire pieces with this glaze you need to fire them at around 800ºC.

Alkaline glazes

Alkaline glazes are glazes whose main flux is an alkali such as sodium, lithium, or potassium oxide and alumina. These glazes are characterized by the fact that they are very resistant and mostly transparent.

So if you want to achieve a crackle effect, this glaze is highly recommended.

Salt glazes

These glazes are formed midway through the process because, with salt-glazed pieces, ordinary salt is added to the hot kiln, which acts as a flux and reacts with the silica in the clay.

This means that the glaze is not applied directly to the piece like other glazes. The salt is simply added through an opening in the kiln when it is over 920°C and with the heat, the salt is added to the piece and turns into a glaze.

It also provides a great finish on the clay. It has a slightly rough texture, like that of an orange peel, and has a vitreous finish, meaning it is shiny and durable.

This glaze is also commonly used for European earthenware pieces.

Ash glazes

Ash glazes are derived from burnt wood or plants that are washed, filtered, and mixed with clay or feldspar. The pots are then dipped in the resulting glaze and dried before firing.

What is special about this type of icing is that when it goes into the oven, the heat from the kiln causes all of the elements that make up the icing to liquefy and vitrify into a glossy crust.

Different colors can be achieved by using different types of ash. For example, walnut ash has an off-white finish, while oak produces pale, soft blues and greens.

The ash glaze is very important and is used in East Asia.

Feldspar glazes

Feldspar glazes are glazes based on feldspar, a group of minerals mainly silica and calcium carbonate. They are perfect for high temperatures, around 1,200°C.

2. The type of clay

A very important consideration before choosing the glaze is the clay you will be applying the glaze to. Depending on the clay, different temperatures are used for firing. A glaze should therefore be suitable for the same firing temperature.

For example, high-fired glazes are perfect for stoneware and porcelain. Porcelain has to be fired at a temperature of more than 1,400 °C and stoneware at 1,300 °C, i.e. at very high temperatures.

3. Presentation and quantity

Ceramic glazes are available as a powder and as a suspension, i.e. as a liquid. Both presentations reach the two important temperatures of glazes, the low (between 980 and 1,060°C) and the high temperature (between 1,200 and 1,280°C).

Powder glazes must be mixed with water before being applied to the workpiece. In general, the mixture is made in a ratio of 60% glaze powder to 40% water.

Suspension glazes are supplied ready to use, you do not have to touch them. For this reason, ceramists today tend to use liquid glazes because they are much more practical.

Aside from the fact that liquid glazes give great results, they are very easy to apply and incorporation into the clay is very easy.

Both powder and liquid glazes come in a variety of styles, e.g. B. transparent, matt, cracked, or opaque with gloss.

Before starting work, you should calculate how much glaze you need to use for the planned pieces.

Powder glazes are available in 20, 40, 80, and 500 g or in 1, 5, and 25 kg bags. Suspension glazes are available in 240, 250 ml and 1-liter containers.

4. Price of glazes

Glazes are not overly expensive, but you can only get them in select specialty stores or online. It’s best to compare the prices. However, remember that the cheapest product is not always the most suitable.

Application techniques

- By pouring

- By dipping

- With brush

- Airbrushing

- under-cover

- On-cover and third firing

The first 3 techniques, pouring, dipping, and brushing, are used most frequently in the workshops. These are the easiest to use.

The 5 best glazes on the market

Ceramic glazes are available at art stores and online stores such as Amazon and eBay. There is a wide range to choose from, but finding them is not difficult.

Of the glazes available online, 5 stand out from the rest, and they are these:

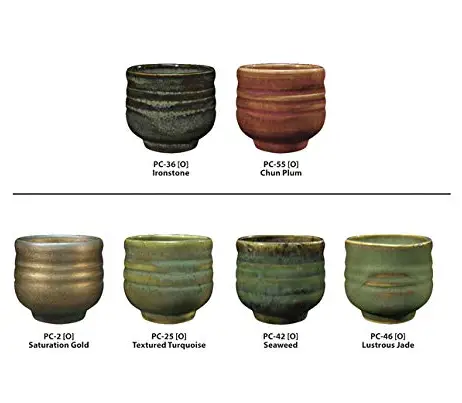

Amaco liquid glaze

- Price: $70

- They are available in 6 nail polish colors

- Lead-free

- Each can contains 472 ml

These are lead-free high-temperature glazes that can be combined very well with stoneware or china clay, which have to be fired at high temperatures due to their components.

These glazes can be used by everyone from beginners to professionals, as they are very easy to use and leave a beautiful finish.

Mayco Stroke & Coat liquid glazes

- Price: $45

- Available in 12 colored lacquers

- Perfect for high temperatures

- Each can contains 59 ml

They are resistant to high temperatures, so they must be used with clays that are above

1,200 °C must be fired. If you want a translucent result on your pieces you can apply just 1 coat, while if you want an opaque finish but still want bright and eye-catching colors you can apply 3 coats.

These glazes are perfect and highly recommended for people who are glazing their pieces for the first time. They are very easy to apply, the colors are very vibrant, and look great on clay.

If you want to use white for your pieces, you will need to apply multiple coats to get a good result. But whether you apply just a few or several, the pieces will always look very shiny.

A major advantage of these glazes is that they are non-toxic and contain no lead, so they can also be used on items intended for food, e.g. B. on dishes. And of course, you can use these on many other pieces for your household.

Amaco enamel

- Price: $20

- Burning at a high temperature

- The jar contains ½ L

Ideal for high-temperature-resistant clays such as porcelain and earthenware, this glaze is a very versatile product that mixes easily with other glazes while still providing an excellent result.

It’s a glaze that needs to be applied in multiple layers to get a great result, and that’s exactly what users say it does with this glaze. It looks great after several coats of paint on clay.

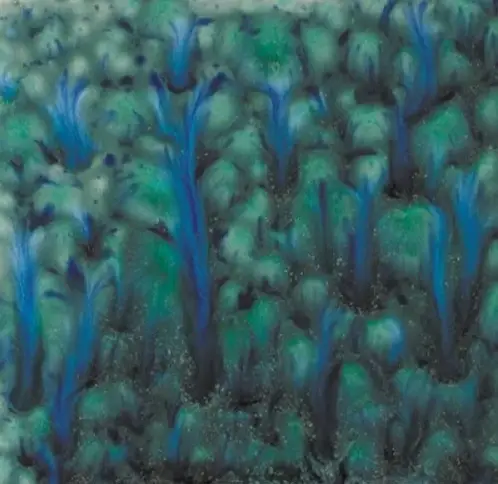

Mayco Selva Glas Gem Glaze

– Price: $9

– It is suitable for medium and high temperatures

– The can contains 4.2 ounces

This enamel looks spectacular at first sight as it features a pattern created during the firing process. Your piece may not look like the reference image when it comes out of the oven, but we assure you it will still look amazing.

It can be combined with other glazes to mix colors if you wish. However, if you want to achieve different shades with this glaze alone, you can simply apply less or more glaze.

If you apply two coats, you will get a very light shade of green, but if you apply more than two coats, the tint will change to a bluish color. But the temperature at which you bake the piece also contributes to this color change.

It is a different glaze that can be fired at high temperatures and is very easy to work with, making it one of the most recommended glazes on the market.

Turquoise blue powder glaze from Penguin pottery

– Price: $15

– Low, medium, and high temperature

– Bag contains 113 g

Among the many liquid glazes, you can find in online stores, this is a good choice if you are looking for powder glazes. It got 4 stars out of 5 because the results on clay are very good.

It also mixes easily with other powder icing colors from this brand.

Since it is a powder glaze, you have to take into account that it is a bit more complicated to get the desired result. It depends on how strong the color of the powder is and how much of it you have to mix to be able to apply it to the piece.

Once you’ve made the mix, it’s very easy to apply and you can always use the leftover icing on other pieces.