Translated by Nick R

Did you know machines can make ceramics manufacturing much easier and quicker? Throughout this blog, we will let you know everything about 4 machines that will certainly help you a lot in your workshop or home.

Many tools, like pans, scrapers, rollers, and sponges, help you model ceramics, but these tools accompany you in the process. The machines we are about to show can do parts of the process for you, great, don’t you think so?

The 4 tools which you will learn about are:

- Manual extruder for artisanal ceramics

- Ceramic slab roller

- Rotary press for modeling

- Pad printing machine

Table of Contents

Manual extruder for handmade pottery

The ceramic extruder is one of the most used machines in pottery, as it is tremendously helpful at specific moments of the process, such as making the handles of cups, jugs, or any piece that requires it.

The function of this machine is basically to create strips of clay. These can be thick, thin, or in between; it all depends on the thickness of the extruder or the discs of different designs placed at the tip of the machine to make the strips not only circular but in shapes: squares, triangles, rectangles or more.

The manual extruder is really easy to use, so much so that it can be used by children and adults, from the beginner to the expert. What makes it so easy to use is, that you only need to pull down a lever to make it work. We will explain it in detail.

How to use it?

All you have to do is to thoroughly knead a piece of clay and put it into the machine through the upper part and, finally, lower the lever forcibly until the clay starts to come out from the bottom.

Bigger extruders like the one in the picture, have a lever, but smaller ones work by twisting the top handle as if you were screwing something in.

Models you can find it in

You can get some big extruders to stuck on walls like in the picture above, or tiny ones, which you can use in your workshop if you feel you don’t need such a big one.

You may think that one is big, but actually, in workshops, where pieces are made massively, there are gigantic extruders that produce large and thick strips.

Although those are only bought by companies or shops that don’t make pieces by hand, most do large-scale industrial production.

A genius feature of extruders is nozzles or tips or discs, as some call them, of different designs that are placed on the bottom of the machine. They allow getting pieces with shapes different from the cylinder, or many cylinders at a time to increase production efficiency. The above image is an example of this, showing many strips coming out instead of just one as it would be if the extruder did not have any nozzle on it.

These are some nozzle designs that are helpful depending on the piece you are making. For example, they work well if you want to make many thin strips around a cup as decoration. The easiest use you can give it is making coils for modeling with the coiling technique.

Ceramic slab roller

A ceramic roller is also a machine widely used by professional potters since it is practical and saves a lot of time in the process. And as a professional, something you want to consider a lot is good time management.

It has technically the same function as the rollers, which is to create flat surfaces and sometimes print designs or textures on the clay, but with the slab roller, this process may be easier as it requires less physical effort. Besides, the whole slab will have the same thickness, which is difficult to achieve with a wooden roller.

If you want to save time and labor and have better clay slabs to work with, we recommend you to have one of these machines in your workshop. They are really helpful.

How to use it?

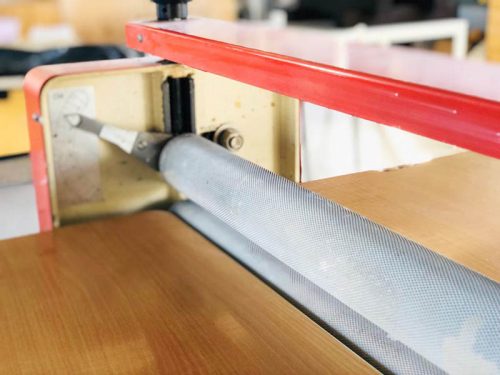

The first thing you should know is that, to use the sheeter, you need the assistance of another person in one step. This machine is composed of 3 rudders that are where the laminator is operated; two rollers and a table.

Also, you have to lay plastic over the table and then put a block of clay between the two rollers to run the slab roller. Following the picture below, the clay goes between the roller that is visible on top and the other one that is about the same height as the table.

Then, with another person, move simultaneously the black knobs, which adjust the height of the top roller to determine the thickness of the slab.

You can adjust the height a little at a time depending on whether the clay block was too big at the beginning.

You must move the big rudder (the red one in the background in the picture) so that the clay starts to flatten slowly. When the slab comes out, you can put it back on and lower the upper roller a little and pass it through again using the red rudder until you have a slab of the thickness, height and length that you want.

Models you can find it in

Some rollers allow you to create single clay sheets with various thicknesses, such as the one we showed you how to use above that allows adjusting each rudder or regulating wheel to your liking. Otherwise, others have these wheels synchronized, that is to say, that the whole sheet will be of the same thickness.

In some rollers, the minimum thickness of a slab is 0.3 mm, while others allow a minimum of 0.5 mm, which is the standard thickness for most commercial pieces.

As the size is another major aspect of a ceramic workshop, rollers are available in different sizes. Moreover, the larger rollers include a table, while others, known as ” table-top rollers”, are much smaller so that they can be moved around the workshop.

There are single roller and double roller sheeters. The best is the latter because they distribute the pressure more accurately and allow you to produce slabs with a uniform thickness and no deformation.

Rotary press for modeling or Jiggering machine

This is the perfect machine if what you want is to stop making your pieces manually, either by hand modeling, lathing, molding, or using the casting technique, because the machine will do everything on your behalf.

The rotary press shapes in less than a minute and can creates any type of piece you could think of: from any tableware item to vases and flower pots for your gardens. It is a machine widely used in workshops or companies engaged in making mass-produced pieces.

And if you are wondering: “How can a machine do in less than a minute what takes me more than 2 hours to do?

This machine is mainly composed of 5 parts:

- Plaster or aluminum mold

- Lever or tool holder where the mold is placed.

- Counterweight to make the lever go up and down.

- 2nd plaster or aluminum mold on the table of the machine where the clay is placed.

- Gearbox to moderate the speed

How to use it?

Use it is really simple, you only have to do three simple things. The first is placing, on the head of the machine, the plaster or aluminum mold of the piece you want to make, either a cup or a plate. Then, you must place a piece of clay in the container below and turn it on to start working.

No kidding, you have to do absolutely nothing else. However, if the machine does not cut the leftover clay edge, you will have to do it yourself with a scraper or a knife, but if the machine does it, that is one task less for you to take care of.

Each time the press finishes a piece, you can take it out, place a piece of clay back in the bowl, and set it to work by itself once again.

Models you can find it in

This machine can be found in different sizes depending on the number of heads it has. It may have only one, or two of them working simultaneously to make more pieces every minute.

You must know that there are no small presses, they are all big; some are smaller because of their heads, but they always occupy considerable space.

Something great about these machines is that they can be customized to make any piece you want. Thus, you don’t buy a press for a bowl; you buy it for a bowl, a plate, a cup, a vase… as you can put the mold you want on it.

Pad printing machine

This pad printer is a spectacular machine for people with poor decorating skills. It does virtually all the work for you, painting piece by piece in detail by transferring the entire design in just a few seconds.

Like most of the machines shown above, this one is also widely used by companies that produce pieces massively. Therefore, if you want to begin selling a lot and, you don’t have many employees, you can make use of this type of machine to help you a lot during the whole process.

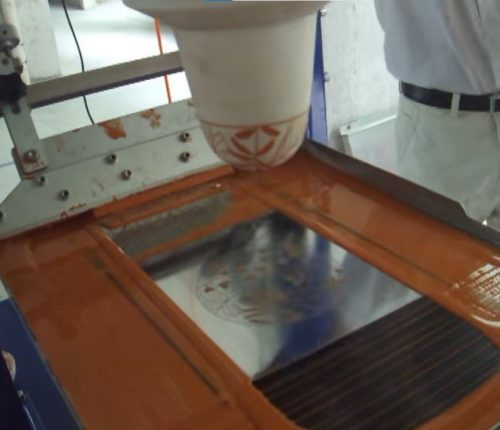

This pad printing machine has 4 parts:

- Silicone pad

- Levers that hold the pads and move up and down

- Steel blade with engraved design

- Gearbox to moderate speed and lever movement

How to use a Pad Printer?

Here, the only thing you have to do is watch for when to remove the piece and insert a new one in the mold or container.

Basically, this machine performs two steps, which we show in the images below. First, the pad, which is made of silicone, presses the engraved design on a steel sheet and adheres the acrylic paint with the design, which is then squeezed on the piecework we are doing to copy the design.

Models in which you can find it

Certain machines have a single pad, while others have more than two that work for printing designs with more than one color of paint. For example, a plate with the same design but in different positions and colors.

In these cases, the machine automatically rotates the plate to each pad as each one adheres to the corresponding design.

__________________________________________________________________________________

We have reached the end of this blog, in which we hope you have learned much more about the world of ceramics, such as these machines that will be of great help to facilitate and speed up all your work.

Keep in mind to use them when making pieces massively, whereas, for more artistic pieces, we recommend you to make them manually.